Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61571539990739

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

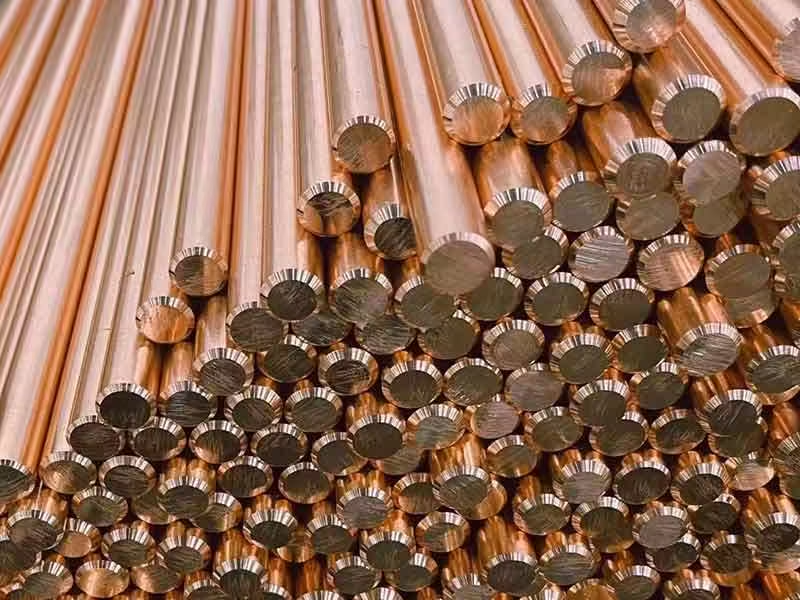

Copper rods are an integral component in electrical applications, prized for their superior conductivity, durability, and versatility. These solid cylindrical rods are typically made from high-purity copper and are used as conductors, grounding electrodes, and structural elements in power distribution, telecommunications, and renewable energy systems.

Understanding the role of copper rods in electrical applications is critical for engineers, electricians, and procurement professionals.

Understanding Copper Rods in Electrical Systems

What Are Copper Rods?

Copper rods are solid, elongated bars made from copper or copper alloys, designed for electrical and mechanical applications. In electrical contexts, copper rods are typically high-purity (99.9% copper or higher), ensuring minimal electrical resistance. Key characteristics include:

- Conductivity: Copper rods offer 100% IACS (International Annealed Copper Standard) conductivity, ideal for power transmission, per EN 60228.

- Diameters: Range from 2 mm to 100 mm, depending on application, such as thin rods for wiring or thick rods for busbars.

- Forms: Available as round, square, or hexagonal rods, with round being most common in electrical uses, per ASTM B187.

- Surface Finish: Smooth or polished to reduce resistance and corrosion, critical for long-term performance.

Copper rods are foundational in France’s power distribution networks, ensuring efficient current flow and system reliability.

Why Are Copper Rods Preferred in Electrical Applications?

Copper rods are the material of choice for electrical applications due to their superior properties. Key advantages include:

- High Conductivity: Conducts electricity with minimal loss (resistivity of 1.68 × 10⁻⁸ Ω·m), outperforming aluminum by 60%, per IEC 60228.

- Corrosion Resistance: Forms a protective patina, extending lifespan in harsh environments, per ISO 9227.

- Thermal Conductivity: Dissipates heat effectively (401 W/m·K), preventing overheating in high-current systems, common in Germany’s industrial grids.

- Recyclability: 100% recyclable without loss of properties, aligning with EU Directive 2008/98/EC on waste management.

These properties make copper rods ideal for applications like grounding in Poland’s renewable energy sector or busbars in Italy’s manufacturing facilities.

Types of Copper Rods for Electrical Use

Copper rods vary in composition and processing to suit specific electrical needs. Common types include:

- Electrolytic Tough Pitch (ETP) Copper Rods: High-purity (99.9% Cu), used for wiring and busbars, offering excellent conductivity, per EN 13601.

- Oxygen-Free Copper (OFC) Rods: 99.99% purity with low oxygen content (<10 ppm), ideal for high-frequency applications like telecommunications, per ASTM B49.

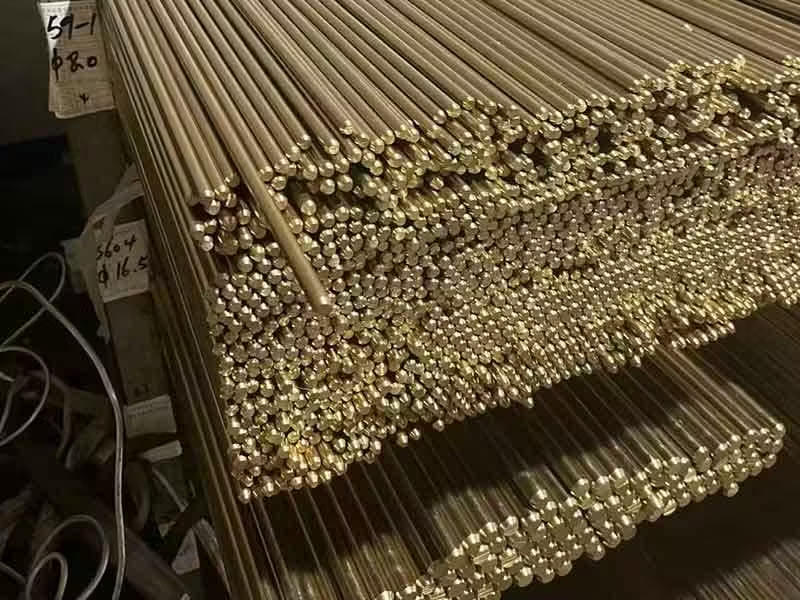

- Copper Alloy Rods: Alloyed with tin or nickel for enhanced strength, used in connectors or grounding, per EN 12163.

- Continuous Cast Copper Rods: Produced for uniform grain structure, ensuring consistent performance in power cables, per ISO 2093.

Each type of copper rod is tailored to specific electrical requirements, supporting diverse applications across Europe’s electrical infrastructure.

Manufacturing and Properties of Copper Rods

Manufacturing Process of Copper Rods

The production of copper rods involves precise processes to achieve high conductivity and durability. Key steps include:

- Electrolytic Refining: Raw copper is purified to 99.9% via electrolysis, removing impurities like sulfur, per ISO 431.

- Continuous Casting: Molten copper is cast into rods (8–25 mm diameter) using continuous casting machines, ensuring uniform grain structure, per EN 1977.

- Hot Rolling: Rods are rolled at 800–900°C to reduce diameter and enhance ductility, per ASTM B49.

- Cold Drawing: Further reduces diameter (2–100 mm) and improves surface finish, increasing tensile strength (200–400 MPa), per EN 13602.

- Annealing: Heat treatment at 400–600°C softens rods, optimizing conductivity and flexibility for wiring, per ISO 1973.

These processes ensure copper rods meet stringent EU standards (e.g., EN 60228), supporting applications like power grids in Spain or grounding systems in the UK.

Physical and Electrical Properties of Copper Rods

The properties of copper rods make them ideal for electrical applications. Key properties include:

- Electrical Conductivity: 100% IACS, with resistance of 1.68 × 10⁻⁸ Ω·m, minimizing energy loss, per IEC 60228.

- Tensile Strength: 200–400 MPa, balancing strength and flexibility for busbars or cables, per EN 13602.

- Thermal Conductivity: 401 W/m·K, ensuring efficient heat dissipation in high-current systems, per ISO 8301.

- Corrosion Resistance: Resists oxidation in humid or saline environments, with a lifespan of 20–50 years, per ISO 9227.

- Density: 8.96 g/cm³, providing structural stability for grounding rods, per ASTM B187.

These properties make copper rods a reliable choice for electrical systems in Germany’s industrial sector or France’s renewable energy projects.

Standards Governing Copper Rods in Electrical Applications

Copper rods are subject to international standards to ensure quality and safety. Key standards include:

- EN 13601: Specifies chemical composition and conductivity for copper rods in electrical applications, widely used in Poland.

- ASTM B187: Defines dimensions and tolerances for copper busbars and rods, critical for Italy’s manufacturing.

- IEC 60228: Governs conductor materials for cables, ensuring copper rods meet conductivity requirements in the UK.

- ISO 2093: Outlines continuous casting processes for high-purity copper rods, supporting Spain’s power cable production.

Compliance with these standards ensures copper rods deliver consistent performance in European electrical systems, per EU Directive 2014/35/EU on low-voltage equipment.

Comparison Table of Copper Rod Types for Electrical Applications

To assist in selecting the appropriate copper rods for electrical projects, the following table compares common types, focusing on composition, conductivity, applications, and advantages. This reference aids engineers and procurement specialists without including pricing information, as requested.

| Copper Rod Type | Composition | Conductivity (% IACS) | Typical Applications | Advantages | Limitations |

|---|---|---|---|---|---|

| ETP Copper Rods | 99.9% Cu, 0.04% O | 100–101 | Power cables, busbars | High conductivity, cost-effective | Slightly lower purity for high-frequency use |

| OFC Copper Rods | 99.99% Cu, <10 ppm O | 101–102 | Telecommunications, audio systems | Superior conductivity, low signal loss | Higher production complexity |

| Copper-Tin Alloy Rods | 98% Cu, 1–2% Sn | 80–90 | Connectors, grounding rods | Enhanced strength, corrosion resistance | Reduced conductivity |

| Copper-Nickel Alloy Rods | 90% Cu, 10% Ni | 10–20 | Marine grounding, high-corrosion environments | High corrosion resistance | Low conductivity, niche use |

| Continuous Cast Rods | 99.9% Cu | 100–101 | Power cables, wiring | Uniform grain, consistent performance | Limited to specific diameters |

This table illustrates how copper rods vary in suitability for applications, from power transmission in Germany to telecommunications in France, per standards like EN 13601 and ASTM B187.

Applications of Copper Rods in Electrical Systems

Copper Rods in Power Transmission and Distribution

Copper rods are critical for efficient power transmission and distribution due to their high conductivity. Key applications include:

- Busbars: Large-diameter copper rods (20–50 mm) conduct high currents (1,000–10,000 A) in substations, per IEC 61439, common in Spain’s grid infrastructure.

- Power Cables: Continuous cast copper rods (8–12 mm) form conductor cores, ensuring low resistance in high-voltage lines, per EN 60228.

- Transformers: Copper rods serve as windings, minimizing energy loss in distribution transformers, used in the UK’s power networks.

Copper rods enhance energy efficiency, supporting Europe’s 2030 energy efficiency targets (Directive 2018/2002).

Copper Rods in Grounding and Lightning Protection

Grounding and lightning protection systems rely on copper rods for safety and reliability. Applications include:

- Grounding Electrodes: Copper rods (12–25 mm diameter, 1.2–3 m length) provide low-resistance paths to earth, per IEC 62305, used in Poland’s renewable energy farms.

- Lightning Conductors: Copper rods connect lightning rods to grounding systems, dissipating high currents (up to 200 kA), per EN 62561.

- Substation Grounding: Copper rods form ground grids, ensuring personnel safety in high-voltage environments, common in Germany.

Copper rods’ corrosion resistance and conductivity make them ideal for long-term grounding solutions.

Copper Rods in Telecommunications and Electronics

In telecommunications and electronics, copper rods enable high-frequency signal transmission. Applications include:

- Coaxial Cables: OFC copper rods (2–8 mm) form inner conductors, minimizing signal loss in 5G networks, per ISO 2093, used in France.

- Printed Circuit Boards (PCBs): Copper rods are drawn into wires for PCB traces, ensuring reliable connectivity, per IPC-A-600.

- Antenna Systems: Copper rods serve as conductive elements in radio and satellite antennas, common in the UK’s telecom sector.

Copper rods’ high purity and low resistance support the growth of Europe’s digital infrastructure.

Copper Rods in Renewable Energy Systems

Renewable energy systems leverage copper rods for efficient power generation and distribution. Applications include:

- Solar Panels: Copper rods form conductive pathways in photovoltaic systems, maximizing energy output, per IEC 61730, used in Spain’s solar farms.

- Wind Turbines: Copper rods serve as busbars and grounding conductors, handling high currents (500–2,000 A), per EN 61400.

- Energy Storage: Copper rods connect battery cells in grid-scale storage, ensuring low resistance, common in Germany’s renewable grids.

Copper rods support Europe’s transition to clean energy, aligning with EU Green Deal objectives.

Practical Considerations for Selecting Copper Rods

Size and Dimension Selection for Copper Rods

Choosing the right size of copper rods ensures compatibility and performance. Key considerations include:

- Diameter: Select 2–8 mm for wiring, 20–50 mm for busbars, or 12–25 mm for grounding, per ASTM B187.

- Length: Standard lengths (1–6 m) suit most applications, with custom cuts for specific needs, per EN 13602.

- Current Capacity: Match diameter to current (e.g., 25 mm for 1,000 A), per IEC 60287, critical for Italy’s substations.

Proper sizing of copper rods optimizes electrical efficiency and system safety, per EU Directive 2014/35/EU.

Environmental and Corrosion Considerations for Copper Rods

Environmental factors influence the longevity of copper rods. Key considerations include:

- Corrosion Resistance: Copper rods resist oxidation but require coatings (e.g., tin) in saline or acidic environments, per ISO 9227, common in Norway’s marine applications.

- Temperature Range: Operate effectively from -40°C to 150°C, with annealing for high-temperature stability, per EN 13601.

- Soil Conditions: Use thicker rods (16–25 mm) or copper-clad steel in corrosive soils for grounding, per IEC 62305.

Selecting copper rods with appropriate corrosion protection ensures durability in Europe’s varied climates.

Installation and Maintenance of Copper Rods

Proper installation and maintenance maximize the performance of copper rods. Key tasks include:

- Installation: Use compression fittings for busbars or exothermic welding for grounding rods, ensuring low resistance, per EN 62561.

- Surface Cleaning: Remove oxidation with abrasive pads to maintain conductivity, critical for France’s telecom systems.

- Inspection: Check for pitting or mechanical damage every 1–2 years, per ISO 12944, especially in Germany’s high-current applications.

Regular maintenance of copper rods ensures long-term reliability and safety in electrical systems.

Environmental and Economic Benefits of Copper Rods

Environmental Sustainability and Copper Rods

Copper rods support sustainability through recyclability and efficiency. Benefits include:

- Recyclability: 100% recyclable, with 50% of EU copper from recycled sources, per Directive 2008/98/EC.

- Energy Efficiency: High conductivity reduces transmission losses (1–2% vs. 3–5% for aluminum), aligning with EU Directive 2018/2002.

- Long Lifespan: 20–50 years in grounding or busbar applications, minimizing replacement needs, per ISO 9227.

Copper rods promote green practices, supporting Europe’s circular economy and energy goals.

Economic Advantages of Copper Rods

Copper rods offer economic benefits through performance and durability. Advantages include:

- Low Maintenance: Corrosion resistance reduces repair costs, critical for Spain’s power grids.

- High Efficiency: Minimizes energy losses, saving operational costs in Germany’s industrial sector.

- Versatility: Single material for wiring, busbars, and grounding reduces inventory costs, per EN 60228.

Copper rods deliver significant ROI, enhancing cost-efficiency in Europe’s electrical infrastructure.

Conclusion

Copper rods are the cornerstone of modern power systems, with their superior conductivity, durability and versatility making them widely used in power transmission, grounding, telecommunications and renewable energy applications.

As industry moves towards energy efficiency and digitalization, copper rods remain a reliable and sustainable solution for building a robust power infrastructure. Whether you are upgrading a substation in Italy, installing a wind turbine in Germany or grounding a telecommunications tower in the UK, choosing the right copper rod will ensure long-term success.

Looking for High-Conductivity Copper Rods?

Our premium copper rods are engineered for superior electrical conductivity, corrosion resistance, and performance. Perfect for power systems, grounding, and high-demand industrial use.

FAQ

What are copper rods in electrical applications?

Copper rods are high-purity, solid copper bars used as conductors, grounding electrodes, or busbars in power, telecom, and renewable energy systems, per EN 13601.

Why are copper rods preferred for electrical use?

Copper rods offer 100% IACS conductivity, corrosion resistance, and recyclability, minimizing energy loss and ensuring durability, per IEC 60228.

What types of copper rods are used in electrical systems?

ETP copper rods for cables, OFC rods for telecom, and copper alloy rods for grounding, each tailored to specific needs, per ASTM B187.

How are copper rods manufactured?

Through electrolytic refining, continuous casting, hot rolling, cold drawing, and annealing, ensuring high conductivity and strength, per EN 1977.

What applications rely on copper rods?

Power transmission (busbars, cables), grounding, telecommunications (coaxial cables), and renewable energy (solar, wind), per IEC 61730 and EN 61400.