내 블로그에 오신 것을 환영합니다!

본론으로 들어가기 전에, 제가 더 많은 정보를 공유하고, 커뮤니티와 소통하고, 업데이트를 게시하는 소셜 미디어 플랫폼에 함께해 주세요. 저와 소통하는 방법은 다음과 같습니다.

페이스북:https://www.facebook.com/profile.php?id=61571539990739

자, 이제 함께 여정을 시작해 볼까요? 여기 있는 내용이 통찰력 있고, 흥미롭고, 가치 있다고 느끼시기를 바랍니다.

목차

소개

When it comes to selecting materials for construction, industrial applications, or even household projects, the choice between sheets of galvanized metal and stainless steel often arises. Both materials offer unique properties and benefits, making them suitable for various applications. Understanding the differences and similarities between these two materials is crucial for making an informed decision.

This comprehensive guide will delve into the characteristics, advantages, and applications of sheets of galvanized metal and stainless steel, helping you choose the right material for your needs.

이해 Sheets of Galvanized Metal

What Are Sheets of Galvanized Metal?

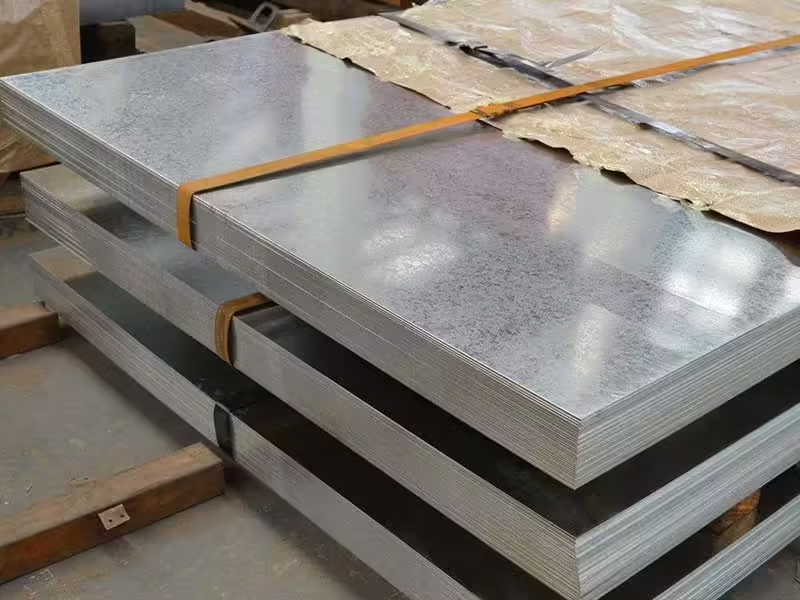

Sheets of galvanized metal are steel or iron sheets that have been coated with a layer of zinc to prevent rust and corrosion. The galvanization process involves either hot-dip galvanizing, where the metal is dipped into molten zinc, or electro-galvanizing, where a thin layer of zinc is applied through an electrochemical process. This coating provides a durable and protective barrier against environmental elements, making galvanized metal sheets ideal for outdoor applications.

Key Properties of Galvanized Metal Sheets

- 부식 저항성: The zinc coating protects the underlying steel from rust and corrosion, extending the lifespan of the material.

- 내구성: Galvanized metal sheets are strong and can withstand harsh weather conditions and physical impacts.

- 낮은 유지 보수: The protective zinc layer reduces the need for frequent maintenance and painting.

- 비용 효율적: Galvanized metal sheets are generally more affordable compared to stainless steel, making them a cost-effective choice for many applications.

스테인리스 스틸 시트 이해

What Are Stainless Steel Sheets?

Stainless steel sheets are made from an alloy of iron, chromium, and other elements such as nickel, molybdenum, and carbon. The chromium content forms a passive oxide layer on the surface, which provides excellent corrosion resistance. Stainless steel sheets are available in various grades, each offering different levels of strength, corrosion resistance, and temperature resistance.

Key Properties of Stainless Steel Sheets

- High Corrosion Resistance: The passive oxide layer on the surface provides excellent resistance to rust and corrosion.

- 강도와 내구성: Stainless steel sheets are strong and can withstand high stress and impact.

- 미적 매력: Stainless steel has a shiny, polished appearance, making it suitable for applications where aesthetics are important.

- 온도 저항: Many grades of stainless steel can withstand high temperatures, making them suitable for industrial applications.

아연 도금 금속판과 스테인리스강판 비교

부식 저항성

Both galvanized metal sheets and stainless steel sheets offer excellent corrosion resistance. However, the type of environment and specific application can influence their performance. Galvanized metal sheets are highly resistant to rust and corrosion due to the protective zinc coating. Stainless steel sheets, on the other hand, rely on a passive oxide layer for corrosion resistance. In highly corrosive environments, such as marine or chemical exposure, stainless steel may offer superior performance.

강도와 내구성

Stainless steel sheets are generally stronger and more durable than galvanized metal sheets. The alloy composition of stainless steel provides high tensile strength and impact resistance. Galvanized metal sheets, while strong, may not match the strength of stainless steel in high-stress applications.

유지 관리 요구 사항

Galvanized metal sheets require minimal maintenance due to the protective zinc coating. The zinc layer can self-heal minor scratches and abrasions, reducing the need for frequent maintenance. Stainless steel sheets, however, may require regular cleaning and maintenance to prevent staining and maintain their appearance. In some cases, stainless steel may need to be polished or treated to prevent corrosion.

비용 고려 사항

Galvanized metal sheets are generally more cost-effective compared to stainless steel sheets. The galvanization process is relatively inexpensive, making galvanized metal a popular choice for many applications. Stainless steel sheets, due to their alloy composition and manufacturing process, are typically more expensive. However, the higher initial cost of stainless steel can be offset by its longer lifespan and lower maintenance requirements in certain applications.

응용 프로그램

Galvanized metal sheets are commonly used in construction, roofing, automotive, and agricultural applications. They are ideal for outdoor use due to their corrosion resistance and durability. Stainless steel sheets are used in a wide range of applications, including food processing, medical equipment, automotive parts, and architectural elements. Their high strength, corrosion resistance, and aesthetic appeal make them suitable for both functional and decorative purposes.

비교표: 아연 도금 금속판과 스테인리스 스틸판

| 재산 | Sheets of Galvanized Metal | 스테인리스 스틸 시트 |

|---|---|---|

| 부식 저항성 | High (due to zinc coating) | Very High (due to passive oxide layer) |

| 힘 | 보통의 | 높은 |

| 내구성 | 높은 | 매우 높음 |

| 유지 | 낮은 | 보통의 |

| 비용 | 낮추다 | 더 높은 |

| 미적 매력 | Matte finish | Shiny, polished appearance |

| 온도 저항 | 보통의 | High (depending on grade) |

| 일반적인 응용 프로그램 | Construction, roofing, automotive, agricultural | Food processing, medical equipment, automotive parts, architectural elements |

아연 도금 금속과 스테인리스 스틸을 선택할 때 고려해야 할 요소

환경 조건

The environment in which the material will be used is a critical factor in the decision-making process. Galvanized metal sheets are suitable for outdoor applications where exposure to moisture and weather elements is common. Stainless steel sheets, however, may be more appropriate for highly corrosive environments, such as marine or chemical exposure.

강도 요구 사항

If the application requires high strength and impact resistance, stainless steel sheets may be the better choice. Stainless steel can withstand higher stress levels compared to galvanized metal, making it suitable for applications where durability is a priority.

Aesthetic Considerations

For applications where appearance is important, stainless steel sheets offer a shiny, polished look that can enhance the visual appeal of the project. Galvanized metal sheets, on the other hand, have a matte finish that may not be as visually appealing.

Maintenance and Lifespan

While galvanized metal sheets require minimal maintenance, stainless steel sheets may need regular cleaning and occasional polishing to maintain their appearance. The lifespan of both materials can be influenced by the environment and specific application. In some cases, the higher initial cost of stainless steel can be offset by its longer lifespan and lower maintenance requirements.

아연 도금 금속 및 스테인리스 강판 사용을 위한 실용적인 팁

적절한 설치

Ensure that galvanized metal and stainless steel sheets are installed correctly to maximize their performance. For galvanized metal sheets, avoid cutting or damaging the zinc coating during installation. For stainless steel sheets, ensure that they are properly sealed and protected from moisture to prevent staining or corrosion.

정기 검사

Regular inspection of galvanized metal and stainless steel sheets is essential for identifying any signs of wear or damage. Inspect galvanized metal sheets for any signs of zinc coating wear or corrosion. For stainless steel sheets, look for any signs of staining or surface damage that may require cleaning or treatment.

청소 및 유지 관리

Clean galvanized metal sheets regularly to remove dirt and debris that can cause corrosion. Stainless steel sheets should be cleaned with a mild detergent and water to prevent staining and maintain their appearance. Avoid using abrasive cleaners or tools that can scratch the surface of the material.

결론

Choosing between sheets of galvanized metal and stainless steel depends on several factors, including environmental conditions, strength requirements, aesthetic considerations, and maintenance needs. Galvanized metal sheets offer excellent corrosion resistance and durability at a lower cost, making them suitable for a wide range of applications. Stainless steel sheets, while more expensive, provide superior strength, corrosion resistance, and aesthetic appeal, making them ideal for high-performance and decorative applications.

By understanding the properties and benefits of each material, you can make an informed decision that meets your specific needs and ensures the longevity and effectiveness of your project.

자주 묻는 질문

아연 도금 금속판과 스테인리스 강판의 주요 차이점은 무엇입니까?

아연 도금 강판과 스테인리스 강판은 몇 가지 주요 측면에서 차이가 있습니다. 아연 도금 강판은 내식성을 높이기 위해 아연으로 코팅되어 있으며 일반적으로 비용 효율성이 더 높습니다. 스테인리스 강판은 철, 크롬 및 기타 원소의 합금으로 만들어져 강도, 내식성, 광택이 뛰어납니다. 스테인리스 강판은 일반적으로 가격이 더 비싸지만 장기적으로 유지 관리 비용이 적습니다.

어떤 재료가 야외용으로 더 적합합니까?

아연 도금 강판은 뛰어난 내식성과 내구성으로 옥외용 소재로 매우 적합합니다. 아연 도금은 하부 강판을 녹과 기상 요인으로부터 보호하여 건설, 지붕 공사, 농업 프로젝트에 비용 효율적인 선택이 될 수 있습니다. 스테인리스강은 옥외용 소재로도 사용 가능하며, 특히 해양이나 화학 물질 노출과 같이 부식성이 높은 환경에서는 더욱 효과적입니다.

아연 도금된 금속판을 어떻게 관리하나요?

아연 도금 금속판을 유지 관리하려면 부식을 유발할 수 있는 먼지와 이물질을 제거하기 위해 정기적인 검사와 청소가 필요합니다. 설치 중에는 아연 코팅을 절단하거나 손상시키지 말고, 녹 발생을 방지하기 위해 긁힘이나 마모가 있는 경우 즉시 수리하십시오. 아연 도금 금속판은 최소한의 유지 관리만 필요하며, 보호 아연층으로 인해 경미한 표면 손상은 자가 치유될 수 있습니다.

스테인리스 강판의 일반적인 용도는 무엇입니까?

스테인리스 강판은 식품 가공, 의료 기기, 자동차 부품, 건축 자재 등 다양한 분야에 사용됩니다. 높은 강도, 내식성, 그리고 미적인 아름다움으로 기능성과 장식성 모두에 적합합니다. 스테인리스 강판은 내열성과 내구성이 요구되는 산업 분야에도 사용됩니다.

아연 도금된 금속판을 칠할 수 있나요?

네, 아연 도금 강판은 도색을 통해 외관을 개선하고 추가적인 보호 기능을 제공할 수 있습니다. 하지만 도색 전에 표면을 깨끗하게 세척하고 프라이머를 칠하는 등 적절한 표면 처리가 필수적입니다. 아연 도금 강판의 아연 코팅은 페인트 접착력을 높여주지만, 제대로 된 표면 처리를 통해 내구성이 뛰어나고 오래가는 마감을 얻을 수 있습니다.