내 블로그에 오신 것을 환영합니다!

본론으로 들어가기 전에, 제가 더 많은 정보를 공유하고, 커뮤니티와 소통하고, 업데이트를 게시하는 소셜 미디어 플랫폼에 함께해 주세요. 저와 소통하는 방법은 다음과 같습니다.

페이스북:https://www.facebook.com/profile.php?id=61571539990739

자, 이제 함께 여정을 시작해 볼까요? 여기 있는 내용이 통찰력 있고, 흥미롭고, 가치 있다고 느끼시기를 바랍니다.

목차

소개

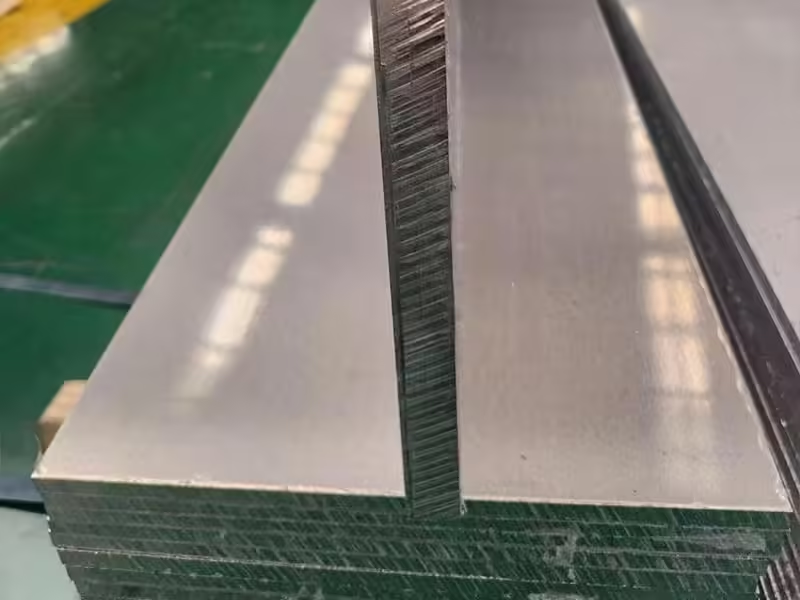

The concept of aluminum plate weight is critical for engineers, fabricators, and designers across industries like aerospace, construction, and manufacturing. Aluminum plates, valued for their lightweight yet strong properties, require precise weight calculations to ensure structural integrity and cost efficiency.

이 가이드에서는 알루미늄 판의 무게를 살펴보고, 계산 방법, 영향 요인 및 응용 분야를 자세히 설명합니다.

Understanding Aluminum Plate Weight

To fully grasp aluminum plate weight, it’s essential to understand what an aluminum plate is and why its weight matters. An aluminum plate is a flat-rolled aluminum product, typically thicker than 0.25 inches, used in applications requiring strength, corrosion resistance, and light weight. The weight of an aluminum plate is determined by its dimensions (length, width, thickness) and the density of the aluminum alloy used, which varies slightly depending on composition.

The significance of aluminum plate weight lies in its impact on design, transportation, and structural performance. In aerospace, minimizing weight is crucial for fuel efficiency, while in construction, accurate weight calculations ensure load-bearing capacity. This section outlines the principles behind aluminum plate weight, setting the stage for a deeper exploration of its influencing factors and applications.

Defining Aluminum Plate Weight

When addressing aluminum plate weight, it refers to the mass of an aluminum plate, calculated using its volume (length × width × thickness) and the density of the alloy, typically around 2.7 g/cm³ for pure aluminum. Alloying elements like magnesium or copper slightly alter density, affecting the final weight. Accurate weight determination is vital for material selection and project planning.

Importance of Aluminum Plate Weight in Industry

Understanding aluminum plate weight is crucial for optimizing designs and ensuring safety. In transportation, lighter plates reduce fuel costs, while in structural applications, precise weight calculations prevent overloading. The lightweight nature of aluminum, combined with its strength, makes it a preferred material, and knowing its weight ensures efficient use across industries.

Factors Affecting Aluminum Plate Weight

Several factors influence aluminum plate weight, from material properties to physical dimensions. This section provides a technical overview of these factors, offering insights for professionals calculating and managing plate weight in their projects.

Alloy Composition and Density

The primary factor affecting aluminum plate weight is the alloy used. Pure aluminum has a density of approximately 2.7 g/cm³, but alloys like 6061 (with magnesium and silicon) or 7075 (with zinc) have densities variations (2.68–2.81 g/cm³). These differences, though small, impact aluminum plate weight, especially in large-scale applications like shipbuilding or aerospace, where even minor weight changes are significant.

판 치수

Aluminum plate weight is directly proportional to its dimensions: length, width, and thickness. Thicker or larger plates have greater volume, increasing weight. For example, a 1-inch-thick, 4×8-foot plate weighs significantly more than a 0.25-inch-thick plate of the same area. Precise measurement of dimensions is critical for accurate weight calculations in engineering designs.

Surface Finish and Processing

Surface treatments, such as anodizing or polishing, can marginally affect aluminum plate weight. Anodizing adds a thin oxide layer, increasing weight slightly (e.g., 0.01–0.05% increase), while milling or grinding may remove material, reducing weight. These factors are often negligible but relevant in precision applications like aerospace, where every gram counts.

Temperature and Environmental Effects

While aluminum plate weight is relatively stable, extreme temperatures can cause thermal expansion or contraction, subtly affecting volume and, thus, weight calculations. In cryogenic or high-heat environments, engineers must account for these changes to ensure accuracy. Environmental corrosion, though minimal due to aluminum’s resistance, may also alter weight over time in harsh conditions.

Manufacturing Tolerances

Manufacturing tolerances can influence aluminum plate weight. Variations in thickness or flatness, within acceptable standards (e.g., ASTM B209), may lead to slight weight differences. For instance, a plate specified at 0.5 inches may vary by ±0.01 inches, impacting the final weight. High-precision applications require tight tolerances to minimize discrepancies.

Comparison Table and Applications of Aluminum Plate Weight

To clarify aluminum plate weight, the following table summarizes key factors affecting it, their characteristics, and their applications, offering a concise reference for professionals.

| Factor | Characteristic | Application Impact |

|---|---|---|

| 합금 조성 | Density varies (2.68–2.81 g/cm³) based on alloy | Affects weight in aerospace, marine designs |

| 판 치수 | Length, width, thickness determine volume | Critical for structural and transportation uses |

| 표면 마감 | Anodizing adds minor weight; milling reduces it | Relevant in precision manufacturing |

| Temperature Effects | Thermal expansion alters volume slightly | Considered in cryogenic or high-heat applications |

| Manufacturing Tolerances | Variations in thickness affect weight | Impacts precision in engineering designs |

| 부식 저항성 | Minimal weight change due to oxide layer | Ensures long-term weight stability in construction |

| Lightweight Property | Low density compared to steel | Reduces fuel costs in automotive, aerospace |

Applications Influenced by Aluminum Plate Weight

The concept of aluminum plate weight is central to its applications. In aerospace, lightweight 7075 plates are used for aircraft wings, minimizing fuel consumption. In construction, 6061 plates provide structural support for bridges, balancing weight and strength. Automotive industries use aluminum plates for body panels, reducing vehicle weight. Marine applications leverage corrosion-resistant plates for ship hulls, where weight affects buoyancy and fuel efficiency. These examples highlight the importance of accurate weight calculations.

Calculating Aluminum Plate Weight for Specific Uses

To apply aluminum plate weight effectively, calculate it using the formula: Weight = Length × Width × Thickness × Density. For a 6061 alloy plate (density 2.7 g/cm³), a 4×8-foot (122×244 cm), 0.5-inch (1.27 cm) plate weighs approximately 98.4 kg. Use online calculators or software like AutoCAD for precision, ensuring the selected plate meets load, weight, and performance requirements.

Practical Considerations for Managing Aluminum Plate Weight

Managing aluminum plate weight effectively requires understanding its calculation and application. This section offers actionable guidance for engineers, fabricators, and project managers.

Accurate Weight Calculation Methods

To calculate aluminum plate weight, measure dimensions precisely using tools like calipers or laser scanners. Use the alloy’s specific density (e.g., 2.7 g/cm³ for 6061) and the formula Weight = Volume × Density. Convert units consistently (e.g., cm to meters) and account for tolerances. For complex shapes, CAD software can compute weight, ensuring accuracy for structural or transportation applications.

Selecting the Right Alloy for Weight Optimization

Choose an alloy based on weight and performance needs. For lightweight applications, 5052 or 6061 alloys offer low density and good strength. For high-strength needs, 7075 is ideal despite slightly higher density. Consult standards like ASTM B209 or supplier data sheets to match alloy properties to project requirements, optimizing aluminum plate weight.

Handling and Transportation Considerations

Aluminum plate weight affects handling and transportation. Use cranes or forklifts for heavy plates, ensuring load ratings match the calculated weight. For shipping, optimize stacking to minimize volume while avoiding deformation. Lightweight aluminum reduces fuel costs compared to steel, but accurate weight documentation ensures compliance with transport regulations like DOT guidelines.

Fabrication and Machining Impacts

Fabrication processes like cutting, welding, or forming can alter aluminum plate weight. Laser cutting removes minimal material, while extensive milling may reduce weight significantly. Account for these changes in design calculations. Use proper tools (e.g., carbide cutters) to avoid excessive material loss, maintaining weight consistency in precision applications.

Environmental and Sustainability Factors

Aluminum plate weight ties into sustainability. Aluminum’s low density reduces energy consumption in transportation and construction. Its recyclability (over 75% of aluminum ever produced is still in use) minimizes environmental impact. When selecting plates, prioritize recycled aluminum to further reduce carbon footprint, aligning with standards like LEED for green building projects.

결론

Understanding aluminum plate weight is essential for optimizing designs in aerospace, construction, and automotive industries. By calculating weight accurately and selecting appropriate alloys, professionals can enhance efficiency and performance.

This guide provides comprehensive insights to manage aluminum plate weight effectively, ensuring successful project outcomes.

자주 묻는 질문

How do you calculate aluminum plate weight?

Use the formula: Weight = Length × Width × Thickness × Density. For a 6061 plate, multiply volume (in cm³) by 2.7 g/cm³, then convert to desired units.

What factors affect aluminum plate weight?

Alloy composition, dimensions, surface finish, temperature, and manufacturing tolerances influence weight, with density and size being primary factors.

Why is aluminum plate weight important?

It impacts design, transportation, and structural performance, reducing fuel costs in aerospace and ensuring load capacity in construction.

Which alloys are best for minimizing aluminum plate weight?

Alloys like 5052 and 6061 offer low density and good strength, ideal for lightweight applications, while 7075 suits high-strength needs.

Can aluminum plate weight change in different environments?

Thermal expansion in extreme temperatures may alter volume slightly, and long-term corrosion is minimal but could affect weight in harsh conditions.