내 블로그에 오신 것을 환영합니다!

본론으로 들어가기 전에, 제가 더 많은 정보를 공유하고, 커뮤니티와 소통하고, 업데이트를 게시하는 소셜 미디어 플랫폼에 함께해 주세요. 저와 소통하는 방법은 다음과 같습니다.

페이스북:https://www.facebook.com/profile.php?id=61571539990739

자, 이제 함께 여정을 시작해 볼까요? 여기 있는 내용이 통찰력 있고, 흥미롭고, 가치 있다고 느끼시기를 바랍니다.

목차

소개

버스바, 루핑, 열교환기 또는 PCB 제조와 같은 용도에 구리 기판을 사용할 경우 적절한 두께를 선택하는 것이 매우 중요합니다. 구리 기판의 두께는 전도성, 기계적 강성, 무게, 유연성 및 전체 비용에 영향을 미칩니다. 적절한 두께를 사용하면 과도한 비용이나 사양 미달 없이 신뢰성과 성능을 보장할 수 있습니다.

구리판 두께 측정 이해

구리 시트의 두께는 제곱 피트당 온스, 게이지 번호, 인치의 천분의 일(밀), 밀리미터 등 다양한 형식으로 표현할 수 있습니다.

가벼운 구리 시트의 무게는 평방 피트당 약 16온스이고 두께는 약 0.55mm입니다.

무거운 구리판은 두께가 1mm가 넘고 무게도 훨씬 더 많이 나갑니다.

구리판을 정확하게 선택하려면 일반적인 두께 변환에 익숙해야 합니다.

구리판의 일반적인 두께 범위

초박형 포일 및 마이크로 구리(0.03mm 미만)

회로 기판 라미네이션, 차폐 및 장식용 포일에 사용됩니다. 포일의 두께는 수 마이크론에서 최대 0.03mm(~1.2밀)까지 다양하며, 유연성과 얇은 두께가 가장 중요한 경우에 적합합니다.

경량 시트(0.3~0.8mm / ~8~20oz)

일반적인 무게는 8온스(~0.27mm), 16온스(~0.55mm), 20온스(~0.69mm)입니다. 이 시트는 건축용 마감재, 홈통, 싱크대, 간판, 그리고 성형성과 적당한 강도가 모두 필요한 경량 구조물에 널리 사용됩니다.

중간~무거운 시트(1.0~1.6mm / ~32~48oz)

두께 1.1~1.6mm 정도의 중간-두께 구리판은 열교환기, 무거운 지붕재, 구조용 트림 부품, 산업용 주석 도금 부품 등의 용도를 지지합니다. 강성과 전도성의 균형을 유지합니다.

두꺼운 구리판(2mm 이상 ~ 인치)

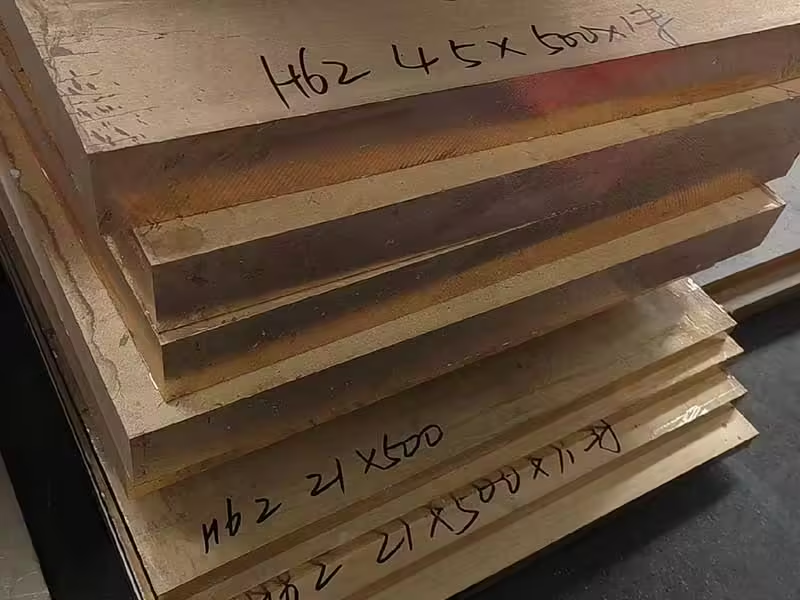

2mm에서 수 인치까지의 판재는 툴링, 대형 버스바 생산, 산업용 기계 블랭크 또는 맞춤 제작에 사용됩니다. 이러한 "판재"는 특수 취급 및 절단 장비가 필요한 경우가 많습니다.

구리판 두께에 대한 응용 프로그램별 고려 사항

전기 및 전력 응용 분야

버스 바, 접지판, 버스 수집기의 경우 엔지니어는 종종 두꺼운 구리판(2~10mm)을 선택하여 전기 저항을 최소화하고 열 성능을 극대화합니다.

건축 및 장식용

지붕, 플래싱, 싱크대 제작, 장식용 패널 등의 용도에서는 일반적으로 0.3mm(8oz)에서 1.0mm(32oz) 사이의 시트 두께를 사용하여 내구성과 성형 용이성의 균형을 맞춥니다.

전자, PCB 및 차폐

인쇄 회로 기판은 전류 용량이나 신호 무결성 요구 사항에 따라 17µm에서 100µm 이상의 구리 호일 층을 사용하는 경우가 많습니다. 차폐 또는 적층 구리 호일 애플리케이션도 이 초박형 범주에 속합니다.

산업 제조 및 중장비

두께가 2mm가 넘는 두꺼운 구리 시트는 견고성과 가공 허용 오차가 중요한 압력 용기, 장비 도금, 용접 부품 또는 스탬핑 산업 부품에 일반적으로 사용됩니다.

비교표: 사용 사례별 구리판 두께

| 두께 범위 | 설명 / 대략적인 크기 | 일반적인 응용 프로그램 |

|---|---|---|

| <0.03 mm (초박형) | 구리 호일, 1밀 이하 | PCB 층, EMI 차폐, 장식용 호일 |

| 0.3~0.8mm(8~20온스) | 가벼운 시트 | 홈통, 트림, 싱크대, 외벽, 간판 |

| 1.1~1.6mm(32~48온스) | 중간-무거운 시트 | 열교환기, 견고한 건축 패널 |

| >2mm ~ 인치 | 두꺼운 산업용 판 | 버스 바, 툴링 블랭크, 구조 제작 |

왜 적절한 두께를 선택해야 할까요? 성능에 미치는 영향

구리판이 두꺼울수록 전도성, 구조적 지지력, 내구성이 향상되지만 무게와 비용이 증가합니다. 구리판이 얇을수록 유연성, 취급 편의성, 재료비가 낮아지지만 강성이나 전류 용량이 저하될 수 있습니다.

따라서 성능과 비용 효율성의 균형을 보장하려면 적용 요구 사항에 따라 두께를 선택하세요.

적절한 구리판 두께 선택을 위한 팁

- 목표를 명확하게 정의하세요. 유연성, 전기적 성능, 하중 지지 용량과 같은 측면이 가장 중요한가요?

- 공급업체나 업계 표준에 맞는 구리 무게 대 두께 변환을 확인하세요.

- 게이지 허용 오차와 구리 순도를 확인하려면 인증된 재료 문서를 요청하세요.

- 성형성, 마감 또는 적합성이 기대에 부합하는지 확인하기 위해 샘플 패널이나 프로토타입을 테스트합니다.

- 선택한 두께에서 굽힘, 절단 또는 용접이 제작 공정에서 지원되는지 평가하세요.

결론

구리판과 그 일반적인 두께를 이해하면 성능 요구 사항에 맞는 재료를 선택하는 데 도움이 됩니다. 프로젝트에 맞는 구리판 선택, 조달 또는 맞춤 제작에 도움이 필요하시면 전문가의 지원을 받으실 수 있습니다.

오늘 저희에게 연락하세요 귀하의 요구 사항을 논의하고 귀하의 응용 분야에 적합한 구리 시트 두께를 얻을 수 있도록 도와드리겠습니다.

자주 묻는 질문

버스바에 일반적으로 사용되는 구리판의 두께는 얼마입니까?

일반적으로 2mm 이상의 두꺼운 구리판은 낮은 전기 저항과 구조적 내구성을 제공하며, 이는 전력 분배 막대에 필수적입니다.

손으로 아주 얇은 구리판을 만들 수 있나요?

네. 두께가 0.03mm 이하인 구리 호일은 가공성이 뛰어나 손으로 쉽게 모양을 만들 수 있지만, 더 두꺼운 시트를 만들려면 도구나 기계가 필요합니다.

구리 게이지 시스템은 다른 금속과 다릅니까?

네. 구리 게이지 차트는 구리에만 적용되며 표준 강철이나 알루미늄 게이지 표준이 아닌 제곱 피트당 온스를 사용합니다.

구리가 두꺼울수록 항상 성능이 더 좋은가요?

항상 그런 것은 아닙니다. 유연한 패널이나 장식용으로 사용하는 경우, 구리가 전도성이나 강도 요건을 충족하는 한 더 얇은 게이지가 더 나을 수 있습니다.

일반적으로 제조되는 가장 얇은 구리판은 무엇입니까?

두께가 0.03mm(약 17µm 또는 1온스) 이하인 구리 호일이 일반적이며, 특수 호일은 더 얇아질 수 있지만 더 취약합니다.