Chào mừng đến với Blog của tôi!

Trước khi đi sâu vào nội dung, tôi rất muốn bạn tham gia cùng tôi trên các nền tảng truyền thông xã hội của tôi, nơi tôi chia sẻ thêm nhiều hiểu biết sâu sắc, tương tác với cộng đồng và đăng các bản cập nhật. Sau đây là cách bạn có thể kết nối với tôi:

Facebook:https://www.facebook.com/profile.php?id=61571539990739

Bây giờ, chúng ta hãy cùng nhau bắt đầu hành trình. Tôi hy vọng bạn thấy nội dung ở đây sâu sắc, hấp dẫn và có giá trị.

Mục lục

Giới thiệu

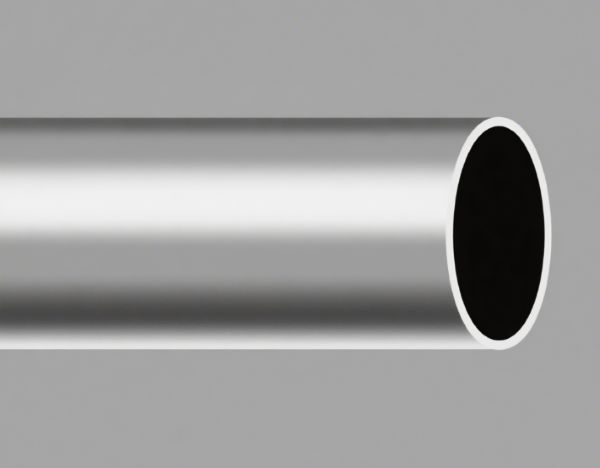

Khi nói đến khả năng vận chuyển chất lỏng, độ bền kết cấu và khả năng chống ăn mòn, ống thép không gỉ đã trở nên thiết yếu trong nhiều ngành công nghiệp. Nhưng giữa vô số loại ống khác nhau, bạn có thể tự hỏi: ống thép không gỉ liền mạch là gì và tại sao nó thường được ưa chuộng hơn ống hàn?

Hướng dẫn này cung cấp cái nhìn toàn diện về ống thép không gỉ liền mạch—chúng là gì, được sản xuất như thế nào, được sử dụng ở đâu và tại sao chúng có thể phù hợp nhất cho dự án tiếp theo của bạn.

Ống thép không gỉ liền mạch là gì và nó được sản xuất như thế nào?

Ống thép không gỉ liền mạch là sản phẩm hình trụ rỗng được làm từ một khối thép không gỉ duy nhất, không có mối hàn hay mối nối. Không giống như ống hàn, ống thép liền mạch được sản xuất bằng quy trình đùn phôi rắn hoặc cán nóng. Tính chất liền mạch này đảm bảo cấu trúc đồng nhất, độ bền cao và hiệu suất chịu áp lực tốt hơn.

Tổng quan về quy trình sản xuất

- Chuẩn bị phôi: Một phôi thép không gỉ tròn được nung nóng cho đến khi dễ uốn.

- Xỏ khuyên:Phôi được đục lỗ bằng một trục để tạo ra phần rỗng ở giữa.

- Cán nóng hoặc kéo nguội:Phôi rỗng được cán hoặc kéo theo kích thước yêu cầu.

- Ủ: Xử lý nhiệt được áp dụng để tăng cường các tính chất cơ học.

- Ngâm chua và hoàn thiện: Loại bỏ tạp chất bề mặt để cải thiện khả năng chống ăn mòn.

Quá trình này loại bỏ mối hàn thường thấy ở các ống hàn, thường là điểm yếu nhất khi chịu áp suất hoặc bị ăn mòn.

Lợi ích của việc sử dụng Seamless Ống thép không gỉ

Việc lựa chọn ống thép không gỉ liền mạch mang lại một số lợi thế đặc biệt quan trọng trong môi trường có áp suất cao và độ tinh khiết cao.

Sức mạnh và khả năng chịu áp lực

Ống liền mạch có kết cấu chắc chắn hơn ống hàn nhờ tính đồng nhất và không có điểm hàn yếu. Điều này khiến chúng phù hợp cho các ứng dụng liên quan đến áp suất cao, ứng suất cơ học hoặc nhiệt độ khắc nghiệt.

Chống ăn mòn

Ống thép không gỉ liền mạch có khả năng chống ăn mòn vượt trội, đặc biệt là trong môi trường có hóa chất, độ ẩm hoặc muối. Điều này rất cần thiết trong các ngành công nghiệp như hóa dầu, dược phẩm và chế biến thực phẩm.

Sự sạch sẽ và tinh khiết

Trong các ứng dụng sạch—như hệ thống lọc nước hoặc đường ống y tế—phần bên trong trơn nhẵn, không có mối nối của đường ống liền mạch giúp giảm nguy cơ nhiễm bẩn và tích tụ vi khuẩn.

Độ bền và độ tin cậy

Ít điểm hỏng tiềm ẩn hơn có nghĩa là tuổi thọ dài hơn, giảm bảo trì và độ tin cậy cao hơn, đặc biệt đối với các hệ thống quan trọng trong nhà máy điện hoặc nhà máy lọc dầu khí.

Ứng dụng của ống thép không gỉ liền mạch

Bạn sẽ thấy ống thép không gỉ liền mạch được sử dụng trong nhiều ngành công nghiệp khác nhau nhờ vào đặc tính hiệu suất của nó.

| Ngành công nghiệp | Ví dụ ứng dụng | Đáp ứng các yêu cầu chính |

|---|---|---|

| Dầu khí | Vận chuyển đường ống áp suất cao | Khả năng chịu áp suất, kiểm soát ăn mòn |

| Chế biến thực phẩm | Vận chuyển chất lỏng vệ sinh | Khả năng làm sạch, bề mặt không bị ô nhiễm |

| Sản xuất điện | Ống nồi hơi, bộ trao đổi nhiệt | Khả năng chịu nhiệt, độ bền |

| Xử lý hóa chất | Đường vận chuyển axit và kiềm | Khả năng chống ăn mòn, tính toàn vẹn về cấu trúc |

| Hàng không vũ trụ | Hệ thống thủy lực và nhiên liệu | Sức mạnh nhẹ, độ chính xác |

| Sự thi công | Khung cấu trúc và hỗ trợ | Sức chịu tải, hoàn thiện thẩm mỹ |

Bằng cách lựa chọn đúng loại và kích thước, ống liền mạch có thể được điều chỉnh để phù hợp với các điều kiện cơ học và hóa học cụ thể của ứng dụng của bạn.

Ống thép không gỉ liền mạch và hàn: So sánh nhanh

Hiểu được những khác biệt cốt lõi có thể giúp bạn quyết định loại ống thép không gỉ nào phù hợp với nhu cầu của mình.

| Tính năng | Ống thép không gỉ liền mạch | Ống thép không gỉ hàn |

|---|---|---|

| Quy trình sản xuất | Đùn từ phôi rắn | Tấm cán và hàn |

| Đường hàn | KHÔNG | Đúng |

| Xử lý sức mạnh và áp suất | Cao hơn | Vừa phải |

| Chống ăn mòn | Cao hơn | Thay đổi tùy theo chất lượng mối hàn |

| Trị giá | Cao hơn | Thấp hơn |

| Có sẵn các kích cỡ | Giới hạn ở đường kính rất lớn | Dễ dàng chế tạo ở kích thước lớn |

Ống thép không gỉ liền mạch thường được lựa chọn khi độ bền, độ tinh khiết và độ bền là yếu tố quan trọng, đặc biệt là trong các ứng dụng có giá trị cao, nơi không thể tránh khỏi nguy cơ hỏng hóc.

Tại sao ống liền mạch lại quan trọng trong cơ sở hạ tầng hiện đại

Với sự gia tăng của các dự án cơ sở hạ tầng toàn cầu và các tiêu chuẩn chất lượng ngày càng khắt khe hơn trong nhiều ngành công nghiệp, nhu cầu về ống thép không gỉ liền mạch tiếp tục tăng. Theo dữ liệu gần đây của ngành, ống thép không gỉ liền mạch được dự báo sẽ có nhu cầu ổn định trong các ngành hóa chất và năng lượng nhờ nhu cầu bảo trì thấp và tuổi thọ cao.

Đầu tư vào vật liệu chất lượng như ống liền mạch không chỉ đảm bảo tuân thủ các tiêu chuẩn quy định mà còn giảm thiểu rủi ro, thời gian ngừng hoạt động và chi phí vận hành dài hạn.

Phần kết luận

Tóm lại, việc hiểu rõ ống thép không gỉ liền mạch là gì và so sánh nó với các lựa chọn thay thế khác là rất quan trọng để đưa ra quyết định vật liệu sáng suốt. Vấn đề không chỉ nằm ở chi phí cao hơn; mà còn ở hiệu suất, độ an toàn và hiệu quả vượt trội. Nếu bạn đang hoạt động trong một ngành công nghiệp có rủi ro cao, nơi hiệu suất là yếu tố quan trọng, ống thép không gỉ liền mạch mang lại lợi thế về độ bền và sự an tâm.

Bạn cần hỗ trợ chuyên môn để lựa chọn thông số kỹ thuật ống phù hợp hoặc tìm nguồn cung ứng từ nhà cung cấp đáng tin cậy? Hãy liên hệ với chúng tôi ngay hôm nay và để đội ngũ giàu kinh nghiệm của chúng tôi giúp bạn tìm ra giải pháp tốt nhất phù hợp với ngành nghề và ứng dụng cụ thể của bạn.

Câu hỏi thường gặp

Điều gì làm cho ống thép không gỉ trở nên “liền mạch”?

Ống thép không gỉ liền mạch được làm từ một khối thép rắn, không có đường hàn, tạo ra độ bền và độ tinh khiết cao hơn.

Ống thép không gỉ liền mạch có tốt hơn ống hàn không?

Tùy thuộc vào ứng dụng. Đối với các hệ thống áp suất cao, độ tinh khiết cao hoặc quan trọng, ống liền mạch thường là lựa chọn tốt hơn.

Ống thép không gỉ liền mạch được sử dụng phổ biến nhất ở đâu?

Chúng được sử dụng rộng rãi trong dầu khí, chế biến thực phẩm, nhà máy điện, công nghiệp hóa chất và hàng không vũ trụ vì độ bền và độ sạch của chúng.

Ống liền mạch có đắt hơn không?

Có, do quy trình sản xuất phức tạp hơn. Nhưng chúng mang lại giá trị lâu dài cao hơn trong những môi trường khắc nghiệt.

Có thể sử dụng ống liền mạch làm đường ống nước không?

Chắc chắn rồi. Bề mặt bên trong sạch sẽ và khả năng chống ăn mòn khiến chúng trở nên lý tưởng cho các hệ thống nước sạch và nước uống.