مرحباً بكم في مدونتي!

قبل أن نتعمق في المحتوى، يسعدني انضمامكم إليّ على منصاتي للتواصل الاجتماعي، حيث أشارك المزيد من الأفكار، وأتفاعل مع المجتمع، وأنشر التحديثات. إليكم كيفية التواصل معي:

فيسبوك:https://www.facebook.com/profile.php?id=61571539990739

لنبدأ رحلتنا معًا. آمل أن تجدوا هذا المحتوى ثريًا وجذابًا وقيّمًا.

جدول المحتويات

مقدمة

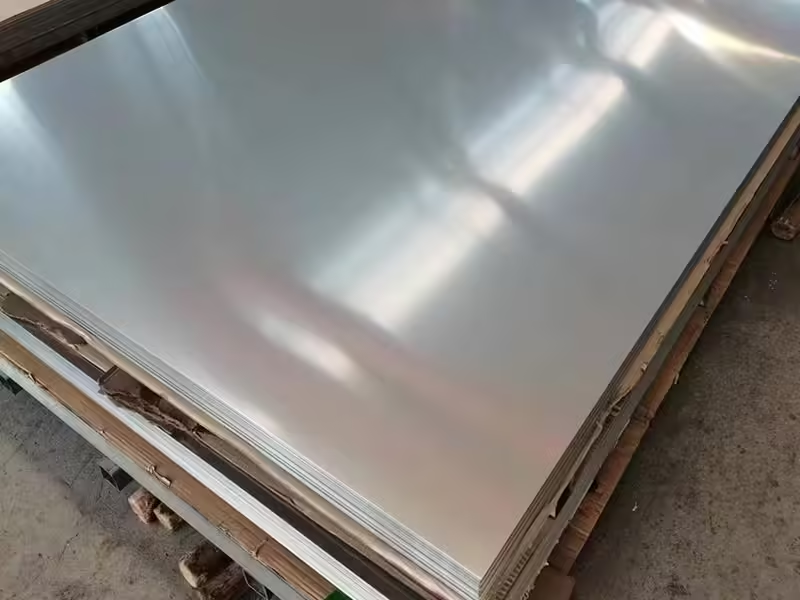

عند اختيار مواد التصنيع، غالبًا ما تكون المتانة ومقاومة التآكل من أهم أولوياتك. وهنا يأتي دور صفائح الفولاذ المقاوم للصدأ 430. إنها فولاذ كروم مستقيم من الحديد، يتميز بخصائص ميكانيكية جيدة ومقاومة متوسطة للتآكل. ليس سعرها مناسبًا فحسب، بل تصمد أيضًا في مجموعة واسعة من التطبيقات.

لكن ما الذي يجعل هذا النوع من الفولاذ متعدد الاستخدامات؟ سواءً كنت تعمل في مجال البناء أو التصنيع أو إنتاج الأجهزة، فإن فهم أماكن وكيفية استخدام صفائح الفولاذ المقاوم للصدأ 430 يساعدك على اتخاذ قرارات أكثر ذكاءً بشأن المواد، وربما خفض التكاليف دون المساس بالأداء.

في هذه المقالة، سنستكشف أفضل استخدامات صفائح الفولاذ المقاوم للصدأ 430، مدعومةً ببيانات واقعية ورؤى الخبراء. إذا كنت تفكر في استخدام هذه المادة في مشروعك القادم، فننصحك بالاستمرار في استخدامها.

فهم أساسيات صفائح الفولاذ المقاوم للصدأ 430

يُصنف الفولاذ المقاوم للصدأ 430 على أنه فولاذ مقاوم للصدأ فريتي، يتكون أساسًا من الحديد والكروم. يحتوي على نسبة ضئيلة جدًا من النيكل، مما يجعله أكثر اقتصادًا من الأصناف الأوستنيتية مثل 304. تتميز هذه التركيبة بمقاومة جيدة للتآكل، وقابلية ممتازة للتشكيل، ومقاومة عالية لحمض النيتريك والأحماض العضوية.

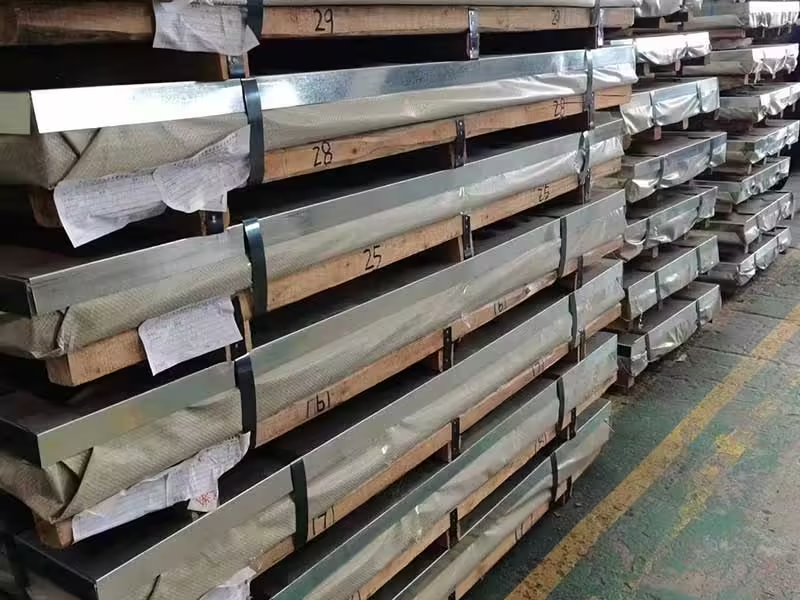

تُستخدم ألواح الفولاذ المقاوم للصدأ 430 عادةً في شكل مدرفل مسطح، وعادةً ما تُدرفل على البارد لزيادة المتانة واللمسة النهائية. تتميز هذه الألواح بمغناطيسيتها، وسهولة قطعها ولحامها، وعدم تصلبها بالمعالجة الحرارية. هذا يجعلها قيّمة بشكل خاص في التطبيقات التي تُعدّ فيها الجمالية، ومقاومة التآكل البسيطة، وضبط التكلفة من الأولويات.

أفضل تطبيقات ألواح الفولاذ المقاوم للصدأ 430

دعونا نلقي نظرة عن كثب على مجالات تميز صفائح الفولاذ المقاوم للصدأ 430 في مختلف الصناعات. يلخص هذا الجدول مجالات الاستخدام الرئيسية:

| مجال التطبيق | لماذا يتم استخدام ألواح الفولاذ المقاوم للصدأ 430 | ملاحظات حول الأداء |

|---|---|---|

| معدات المطبخ | مقاومة جيدة للتآكل، سطح قابل للتلميع | مثالي لظهر الأجهزة والألواح |

| تشطيب السيارات | ليونة عالية وخصائص مغناطيسية | يستخدم في الزخارف الزخرفية وكواتم الصوت |

| المكونات المعمارية | متين في البيئات الداخلية | مناسب لألواح الجدران وأبواب المصاعد |

| المعدات الصناعية | يقاوم التآكل الناتج عن الأحماض العضوية | يستخدم في بيئات العمليات الكيميائية |

| أسطح معالجة الأغذية | غير سامة، وسهلة التعقيم | يلبي معايير النظافة مع التشطيب الصحيح |

| غسالات الصحون والغسالات | مقاومة للحرارة والمنظفات | أداء يدوم طويلاً في البيئات الرطبة |

| العلب الكهربائية | درع غير تفاعلي وغير مغناطيسي (عند الحاجة) | يوفر القوة الهيكلية والقدرة على العمل |

كما ترى، تخدم هذه اللوحة المصنوعة من الفولاذ المقاوم للصدأ مجموعة واسعة من الاحتياجات العملية - خاصة حيث تكون مقاومة التآكل والقابلية للتشكيل المعتدلة أكثر أهمية من القوة الشديدة أو مقاومة الحرارة.

لماذا تُعد ألواح الفولاذ المقاوم للصدأ 430 مثالية للاستخدام في المطبخ

يُعدّ المطبخ أحد أكثر استخدامات صفائح الفولاذ المقاوم للصدأ 430 شيوعًا. بدءًا من ظهور الأفران وصولًا إلى أسطح العمل وألواح الحماية من الرذاذ، فإن مقاومتها للتآكل الناتج عن الطهي وتشطيبها الأملس وسهل التنظيف تجعلها الخيار الأمثل.

قد لا يعمل بشكل جيد مثل الفولاذ المقاوم للصدأ الأوستنيتي في البيئات شديدة الحموضة أو المالحة، ولكن في الإعدادات الداخلية الخاضعة للرقابة مثل المطابخ المنزلية والتجارية، فإنه يوفر توازنًا ممتازًا بين المتانة والقيمة.

وفقًا لبيانات أداء المواد التي أبلغت عنها شركة ASM International، فإن الفولاذ المقاوم للصدأ 430 يحافظ على سلامته البنيوية حتى درجات حرارة تصل إلى حوالي 815 درجة مئوية (1500 درجة فهرنهايت)، مما يجعله مناسبًا للتطبيقات بالقرب من مصادر الحرارة.

دور صفائح الفولاذ المقاوم للصدأ 430 في صناعة السيارات

في عالم السيارات، تُستخدم ألواح الفولاذ المقاوم للصدأ 430 بشكل رئيسي في الزخارف، ومكونات نظام العادم، وأغطية الهيكل السفلي. بفضل متانتها العالية ومقاومتها للتآكل الجوي الخفيف، تحافظ على مظهرها المصقول مع مرور الوقت.

تجعل الخاصية المغناطيسية للنيكل 430 مفيدة في التطبيقات التي تتطلب الكشف أو التثبيت المغناطيسي. بالإضافة إلى ذلك، ولأنه أقل تكلفة من النيكل عالي الجودة، فإنه يدعم خفض تكلفة مكونات المركبات غير الأساسية.

يختاره العديد من المصنعين خصيصًا للتشطيبات الداخلية وجلود كاتم الصوت، لأنه يوفر مظهرًا أنيقًا دون المساومة على الأداء في ظل الظروف المعتدلة.

الفوائد المعمارية والهيكلية لألواح الفولاذ المقاوم للصدأ 430

ربما رأيتَ ألواح الفولاذ المقاوم للصدأ 430 في المصاعد، وألواح الجدران، وحتى الديكورات الداخلية. يُضفي هذا الطلاء الناعم، المتوفر عادةً بأسطح لامعة مُلَدَّنة أو مصقولة، مظهرًا جذابًا بصريًا سهل الصيانة.

لأن الفولاذ المقاوم للصدأ 430 يتميز بصلابة نسبية، فإنه لا يتشوه بسهولة، مما يجعله خيارًا ممتازًا للتطبيقات الإنشائية التي تتطلب الجمالية والصلابة. ويُستخدم بشكل شائع في التركيبات الداخلية، والجدران الفاصلة، وألواح السلالم المتحركة.

خاتمة

سواء كنت تُصنّع الأجهزة المنزلية، أو تُصمّم ديكورات معمارية، أو تُزوّد الآلات الصناعية بمواد، فإنّ تعدد استخدامات صفائح الفولاذ المقاوم للصدأ 430 لا يُضاهى. فتوازنها بين مقاومة التآكل، وقابلية التشكيل، وسعرها المناسب يجعلها الحل الأمثل لمجموعة واسعة من التطبيقات.

مع أنها غير مناسبة للبيئات البحرية أو عالية الكلوريد، إلا أنها تتفوق في البيئات الداخلية وشبه الخاضعة للرقابة، خاصةً عندما تكون الجمالية والفعالية من حيث التكلفة من الأولويات. إذا كنت تفكر في استخدام هذه المادة، فتأكد من مطابقتها لاحتياجات مشروعك المحددة للحصول على أفضل أداء وقيمة عمرية.

الأسئلة الشائعة

هل لوحة الفولاذ المقاوم للصدأ 430 مقاومة للصدأ؟

إنه مقاوم للصدأ، ولكنه ليس مقاومًا له تمامًا. يعمل جيدًا في الأماكن الداخلية الجافة، ولكنه قد يتآكل في البيئات عالية الرطوبة أو الغنية بالكلوريد.

هل يمكن لحام لوحة الفولاذ المقاوم للصدأ 430؟

نعم، ولكنه يتطلب تقنيات خاصة. التسخين المسبق والتلدين بعد اللحام يُحسّنان قابلية اللحام ويُقللان الهشاشة.

هل الفولاذ المقاوم للصدأ 430 مغناطيسي؟

نعم، إنه مغناطيسي بالكامل بفضل تركيبه الفريتيّ. قد يُفيد هذا في بعض التطبيقات، مثل الألواح المغناطيسية أو المرشحات.

كيف يتم مقارنة 430 مع الفولاذ المقاوم للصدأ 304؟

430 أقل مقاومة للتآكل ولا يحتوي على النيكل، مما يجعله أكثر توفيرًا. ومع ذلك، فهو يوفر متانة كافية للعديد من الاستخدامات، كما أنه أسهل في التلميع.

ما هي التشطيبات السطحية المتوفرة للوحة الفولاذ المقاوم للصدأ 430؟

تشمل التشطيبات الشائعة #4 (مصقول)، وBA (مُلَطَّف لامع)، و2B (مطفي). يعتمد اختيارك للتشطيب على احتياجاتك الجمالية والوظيفية.

ما هي التشطيبات السطحية المتوفرة للوحة الفولاذ المقاوم للصدأ 430؟

تشمل التشطيبات الشائعة #4 (مصقول)، وBA (مُلَطَّف لامع)، و2B (مطفي). يعتمد اختيارك للتشطيب على احتياجاتك الجمالية والوظيفية.