مرحباً بكم في مدونتي!

قبل أن نتعمق في المحتوى، يسعدني انضمامكم إليّ على منصاتي للتواصل الاجتماعي، حيث أشارك المزيد من الأفكار، وأتفاعل مع المجتمع، وأنشر التحديثات. إليكم كيفية التواصل معي:

فيسبوك:https://www.facebook.com/profile.php?id=61571539990739

لنبدأ رحلتنا معًا. آمل أن تجدوا هذا المحتوى ثريًا وجذابًا وقيّمًا.

جدول المحتويات

مقدمة

عند اختيار مواد البناء، أو التطبيقات الصناعية، أو حتى المشاريع المنزلية، غالباً ما يبرز خيار بين صفائح المعدن المجلفن والفولاذ المقاوم للصدأ. تتميز كلتا المادتين بخصائص ومزايا فريدة، مما يجعلهما مناسبتين لتطبيقات متنوعة. لذا، يُعدّ فهم أوجه الاختلاف والتشابه بين هاتين المادتين أمراً بالغ الأهمية لاتخاذ قرار مدروس.

سيتناول هذا الدليل الشامل خصائص ومزايا وتطبيقات صفائح المعدن المجلفن والفولاذ المقاوم للصدأ، مما يساعدك على اختيار المادة المناسبة لاحتياجاتك.

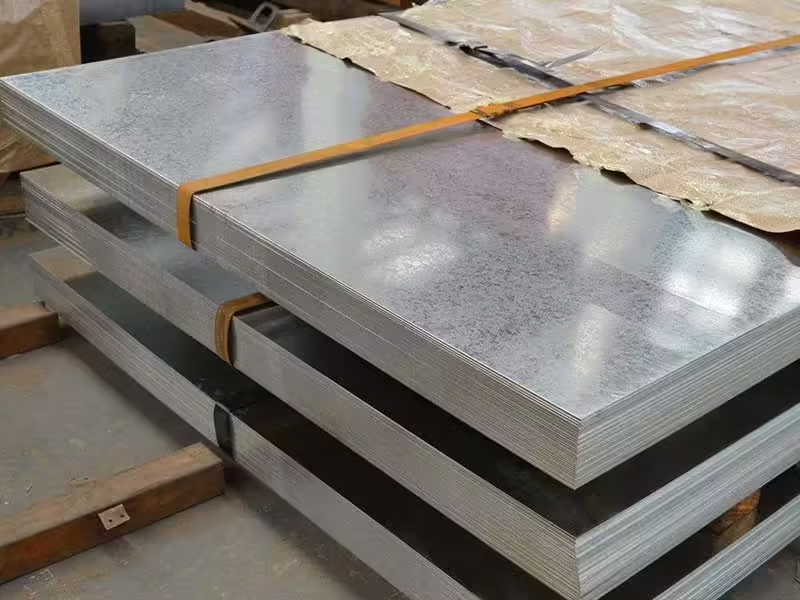

فهم صفائح معدنية مجلفنة

ما هي صفائح المعدن المجلفن؟

صفائح المعدن المجلفن هي صفائح من الفولاذ أو الحديد مطلية بطبقة من الزنك لحمايتها من الصدأ والتآكل. تتضمن عملية الجلفنة إما الجلفنة بالغمس الساخن، حيث يُغمس المعدن في الزنك المنصهر، أو الجلفنة الكهربائية، حيث تُطبق طبقة رقيقة من الزنك من خلال عملية كهروكيميائية. يوفر هذا الطلاء حاجزًا متينًا وواقيًا ضد العوامل البيئية، مما يجعل صفائح المعدن المجلفن مثالية للاستخدامات الخارجية.

الخصائص الرئيسية للصفائح المعدنية المجلفنة

- مقاومة التآكليحمي طلاء الزنك الفولاذ الأساسي من الصدأ والتآكل، مما يطيل عمر المادة.

- متانةتتميز الصفائح المعدنية المجلفنة بقوتها وقدرتها على تحمل الظروف الجوية القاسية والصدمات المادية.

- صيانة منخفضةتقلل طبقة الزنك الواقية من الحاجة إلى الصيانة والطلاء المتكررين.

- فعالة من حيث التكلفةتعتبر الصفائح المعدنية المجلفنة عموماً أرخص ثمناً مقارنة بالفولاذ المقاوم للصدأ، مما يجعلها خياراً فعالاً من حيث التكلفة للعديد من التطبيقات.

فهم صفائح الفولاذ المقاوم للصدأ

ما هي صفائح الفولاذ المقاوم للصدأ؟

تُصنع صفائح الفولاذ المقاوم للصدأ من سبيكة تتكون من الحديد والكروم وعناصر أخرى مثل النيكل والموليبدينوم والكربون. يشكل الكروم طبقة أكسيد واقية على السطح، مما يوفر مقاومة ممتازة للتآكل. تتوفر صفائح الفولاذ المقاوم للصدأ بدرجات مختلفة، تتميز كل منها بمستويات متفاوتة من القوة ومقاومة التآكل ودرجات الحرارة.

الخصائص الرئيسية لصفائح الفولاذ المقاوم للصدأ

- مقاومة عالية للتآكلتوفر طبقة الأكسيد الخاملة على السطح مقاومة ممتازة للصدأ والتآكل.

- القوة والمتانةتتميز صفائح الفولاذ المقاوم للصدأ بقوتها وقدرتها على تحمل الإجهاد العالي والصدمات.

- الجاذبية الجماليةيتميز الفولاذ المقاوم للصدأ بمظهر لامع ومصقول، مما يجعله مناسبًا للتطبيقات التي تكون فيها الجماليات مهمة.

- مقاومة درجة الحرارة: يمكن للعديد من أنواع الفولاذ المقاوم للصدأ تحمل درجات الحرارة العالية، مما يجعلها مناسبة للتطبيقات الصناعية.

مقارنة بين صفائح المعدن المجلفن والفولاذ المقاوم للصدأ

مقاومة التآكل

تتميز كل من الصفائح المعدنية المجلفنة والصفائح الفولاذية المقاومة للصدأ بمقاومة ممتازة للتآكل. ومع ذلك، فإن نوع البيئة والتطبيق المحدد يؤثران على أدائها. تتميز الصفائح المعدنية المجلفنة بمقاومة عالية للصدأ والتآكل بفضل طبقة الزنك الواقية. أما الصفائح الفولاذية المقاومة للصدأ، فتعتمد على طبقة أكسيد خاملة لمقاومة التآكل. في البيئات شديدة التآكل، مثل البيئات البحرية أو عند التعرض للمواد الكيميائية، قد يوفر الفولاذ المقاوم للصدأ أداءً أفضل.

القوة والمتانة

تتميز صفائح الفولاذ المقاوم للصدأ عمومًا بقوة ومتانة أكبر من صفائح المعادن المجلفنة. يوفر تركيب سبيكة الفولاذ المقاوم للصدأ قوة شد عالية ومقاومة للصدمات. أما صفائح المعادن المجلفنة، فرغم قوتها، قد لا تضاهي قوة الفولاذ المقاوم للصدأ في التطبيقات التي تتعرض لإجهاد عالٍ.

متطلبات الصيانة

تتطلب الصفائح المعدنية المجلفنة الحد الأدنى من الصيانة بفضل طبقة الزنك الواقية. إذ تتميز هذه الطبقة بقدرتها على إصلاح الخدوش والتآكلات الطفيفة ذاتيًا، مما يقلل الحاجة إلى الصيانة المتكررة. أما صفائح الفولاذ المقاوم للصدأ، فقد تتطلب تنظيفًا وصيانة دورية لمنع التلطخ والحفاظ على مظهرها. وفي بعض الحالات، قد يحتاج الفولاذ المقاوم للصدأ إلى التلميع أو المعالجة لمنع التآكل.

اعتبارات التكلفة

تُعدّ الصفائح المعدنية المجلفنة عمومًا أقل تكلفةً من صفائح الفولاذ المقاوم للصدأ. فعملية الجلفنة غير مكلفة نسبيًا، مما يجعل المعدن المجلفن خيارًا شائعًا للعديد من التطبيقات. أما صفائح الفولاذ المقاوم للصدأ، نظرًا لتركيبها المعدني وعملية تصنيعها، فهي عادةً أغلى ثمنًا. مع ذلك، يمكن تعويض التكلفة الأولية المرتفعة للفولاذ المقاوم للصدأ من خلال عمره الطويل ومتطلبات صيانته المنخفضة في بعض التطبيقات.

التطبيقات

تُستخدم الصفائح المعدنية المجلفنة على نطاق واسع في مجالات البناء، والأسقف، والسيارات، والزراعة. وهي مثالية للاستخدام الخارجي نظرًا لمقاومتها للتآكل ومتانتها. أما صفائح الفولاذ المقاوم للصدأ، فتُستخدم في تطبيقات متنوعة، تشمل تصنيع الأغذية، والمعدات الطبية، وقطع غيار السيارات، والعناصر المعمارية. وتجعلها قوتها العالية، ومقاومتها للتآكل، وجمالها، مناسبةً للأغراض الوظيفية والزخرفية على حد سواء.

جدول مقارنة: صفائح معدنية مجلفنة مقابل صفائح من الفولاذ المقاوم للصدأ

| ملكية | صفائح معدنية مجلفنة | صفائح الفولاذ المقاوم للصدأ |

|---|---|---|

| مقاومة التآكل | مرتفع (بسبب طلاء الزنك) | مرتفع جداً (بسبب طبقة الأكسيد الخاملة) |

| قوة | معتدل | عالي |

| متانة | عالي | عالية جداً |

| صيانة | قليل | معتدل |

| يكلف | أدنى | أعلى |

| الجاذبية الجمالية | لمسة نهائية غير لامعة | مظهر لامع ومصقول |

| مقاومة درجة الحرارة | معتدل | مرتفع (حسب الدرجة) |

| التطبيقات الشائعة | البناء، التسقيف، السيارات، الزراعة | معالجة الأغذية، والمعدات الطبية، وقطع غيار السيارات، والعناصر المعمارية |

عوامل يجب مراعاتها عند الاختيار بين المعدن المجلفن والفولاذ المقاوم للصدأ

الظروف البيئية

تُعدّ البيئة التي سيُستخدم فيها المعدن عاملاً حاسماً في عملية اتخاذ القرار. تُناسب الصفائح المعدنية المجلفنة التطبيقات الخارجية التي تتعرض للرطوبة وعوامل الطقس بشكل متكرر. أما صفائح الفولاذ المقاوم للصدأ، فقد تكون أكثر ملاءمة للبيئات شديدة التآكل، مثل البيئات البحرية أو البيئات المعرضة للمواد الكيميائية.

متطلبات القوة

إذا كان التطبيق يتطلب قوة عالية ومقاومة للصدمات، فقد تكون صفائح الفولاذ المقاوم للصدأ الخيار الأمثل. يتميز الفولاذ المقاوم للصدأ بقدرته على تحمل مستويات إجهاد أعلى مقارنةً بالمعدن المجلفن، مما يجعله مناسبًا للتطبيقات التي تُعد فيها المتانة أولوية.

الاعتبارات الجمالية

في التطبيقات التي يُعدّ فيها المظهر مهمًا، توفر صفائح الفولاذ المقاوم للصدأ مظهرًا لامعًا ومصقولًا يُحسّن من جاذبية المشروع. أما صفائح المعدن المجلفن، فلها سطح غير لامع قد لا يكون جذابًا بصريًا.

الصيانة والعمر الافتراضي

بينما تتطلب الصفائح المعدنية المجلفنة الحد الأدنى من الصيانة، قد تحتاج صفائح الفولاذ المقاوم للصدأ إلى تنظيف منتظم وتلميع بين الحين والآخر للحفاظ على مظهرها. ويتأثر عمر كلا المادتين بالبيئة والاستخدام المحدد. في بعض الحالات، يمكن تعويض التكلفة الأولية الأعلى للفولاذ المقاوم للصدأ بفضل عمره الأطول ومتطلبات صيانته الأقل.

نصائح عملية لاستخدام الصفائح المعدنية المجلفنة والفولاذ المقاوم للصدأ

التثبيت الصحيح

لضمان أعلى أداء، تأكد من تركيب الصفائح المعدنية المجلفنة والفولاذية المقاومة للصدأ بشكل صحيح. بالنسبة للصفائح المعدنية المجلفنة، تجنب قطع أو إتلاف طبقة الزنك أثناء التركيب. أما بالنسبة للصفائح الفولاذية المقاومة للصدأ، فتأكد من إحكام إغلاقها وحمايتها من الرطوبة لمنع التلطخ أو التآكل.

التفتيش الدوري

يُعدّ الفحص الدوري للصفائح المعدنية المجلفنة والفولاذية المقاومة للصدأ ضروريًا لتحديد أي علامات تآكل أو تلف. افحص الصفائح المعدنية المجلفنة بحثًا عن أي علامات تآكل أو تلف في طبقة الزنك. أما بالنسبة للصفائح الفولاذية المقاومة للصدأ، فابحث عن أي علامات بقع أو تلف سطحي قد يتطلب تنظيفًا أو معالجة.

التنظيف والصيانة

نظّف ألواح المعدن المجلفن بانتظام لإزالة الأوساخ والشوائب التي قد تسبب التآكل. أما ألواح الفولاذ المقاوم للصدأ، فيُنصح بتنظيفها بمنظف معتدل وماء لمنع التلطخ والحفاظ على مظهرها. تجنّب استخدام المنظفات الكاشطة أو الأدوات التي قد تخدش سطح المادة.

خاتمة

يعتمد اختيار الصفائح المعدنية المجلفنة أو الفولاذ المقاوم للصدأ على عدة عوامل، منها الظروف البيئية، ومتطلبات المتانة، والاعتبارات الجمالية، واحتياجات الصيانة. توفر الصفائح المعدنية المجلفنة مقاومة ممتازة للتآكل ومتانة عالية بتكلفة أقل، مما يجعلها مناسبة لمجموعة واسعة من التطبيقات. أما صفائح الفولاذ المقاوم للصدأ، فرغم ارتفاع سعرها، إلا أنها توفر متانة فائقة، ومقاومة عالية للتآكل، ومظهرًا جماليًا جذابًا، مما يجعلها مثالية للتطبيقات عالية الأداء والتطبيقات الزخرفية.

من خلال فهم خصائص وفوائد كل مادة، يمكنك اتخاذ قرار مستنير يلبي احتياجاتك الخاصة ويضمن طول عمر مشروعك وفعاليته.

الأسئلة الشائعة

ما هي الاختلافات الرئيسية بين الصفائح المعدنية المجلفنة والصفائح المصنوعة من الفولاذ المقاوم للصدأ؟

تختلف الصفائح المعدنية المجلفنة عن صفائح الفولاذ المقاوم للصدأ في عدة جوانب رئيسية. تُغطى الصفائح المعدنية المجلفنة بالزنك لتوفير مقاومة للتآكل، وهي عمومًا أقل تكلفة. أما صفائح الفولاذ المقاوم للصدأ، فتُصنع من سبيكة من الحديد والكروم وعناصر أخرى، مما يمنحها قوة أعلى، ومقاومة أفضل للتآكل، ومظهرًا لامعًا. عادةً ما يكون الفولاذ المقاوم للصدأ أغلى ثمنًا، ولكنه يتطلب صيانة أقل على المدى الطويل.

أي المواد أنسب للاستخدامات الخارجية؟

تُعدّ الصفائح المعدنية المجلفنة خيارًا مثاليًا للاستخدامات الخارجية نظرًا لمقاومتها الممتازة للتآكل ومتانتها. يحمي طلاء الزنك الفولاذ الأساسي من الصدأ وعوامل الطقس، مما يجعله خيارًا اقتصاديًا لمشاريع البناء والأسقف والزراعة. مع ذلك، يُمكن استخدام الفولاذ المقاوم للصدأ أيضًا في التطبيقات الخارجية، لا سيما في البيئات شديدة التآكل كالبيئات البحرية أو عند التعرض للمواد الكيميائية.

كيف أحافظ على ألواح المعدن المجلفن؟

تتطلب صيانة الصفائح المعدنية المجلفنة فحصًا وتنظيفًا دوريًا لإزالة الأوساخ والشوائب التي قد تسبب التآكل. تجنب قطع أو إتلاف طبقة الزنك أثناء التركيب، وقم بإصلاح أي خدوش أو سحجات فورًا لمنع الصدأ. لا تحتاج الصفائح المعدنية المجلفنة إلا إلى الحد الأدنى من الصيانة، ويمكنها إصلاح التلف السطحي الطفيف ذاتيًا بفضل طبقة الزنك الواقية.

ما هي الاستخدامات الشائعة لصفائح الفولاذ المقاوم للصدأ؟

تُستخدم صفائح الفولاذ المقاوم للصدأ في تطبيقات متنوعة، تشمل معالجة الأغذية، والمعدات الطبية، وقطع غيار السيارات، والعناصر المعمارية. بفضل قوتها العالية، ومقاومتها للتآكل، ومظهرها الجمالي، تُعدّ هذه الصفائح مناسبة للاستخدامات الوظيفية والزخرفية على حد سواء. كما تُستخدم صفائح الفولاذ المقاوم للصدأ في التطبيقات الصناعية التي تتطلب مقاومة للحرارة ومتانة عالية.

هل يمكن طلاء الصفائح المعدنية المجلفنة؟

نعم، يمكن طلاء الصفائح المعدنية المجلفنة لتحسين مظهرها وتوفير حماية إضافية. مع ذلك، من المهم تحضير السطح جيدًا بالتنظيف والطلاء التمهيدي قبل البدء بالطلاء. يوفر طلاء الزنك على الصفائح المعدنية المجلفنة أساسًا جيدًا لالتصاق الطلاء، لكن التحضير الجيد يضمن الحصول على طبقة نهائية متينة تدوم طويلًا.